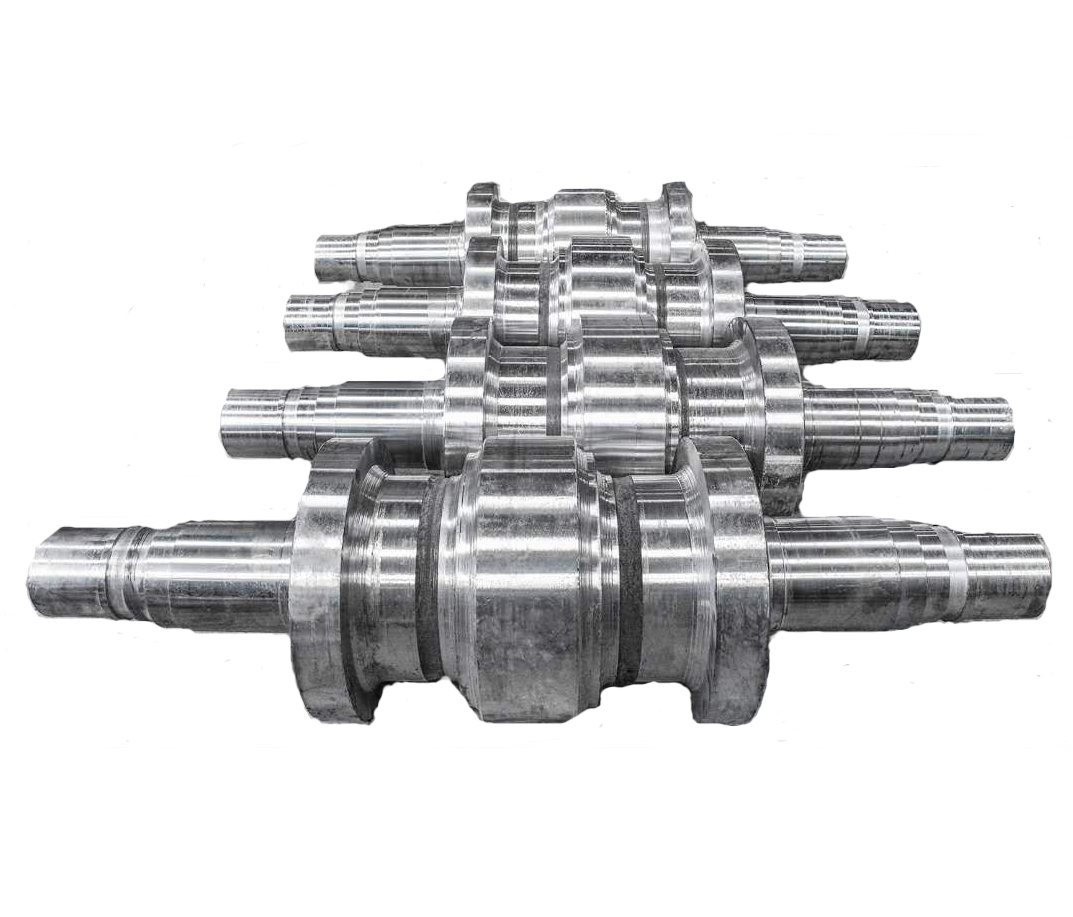

mill roll

mill roll used for produce section steel

- Hardness:HSD58-80

- Size:φ280-800

- Maximum machining length:6000mm

- Product description: mill roll,Rolling mill,Hot rolling mill,Three high rolling mill,Two high rolling mill,Four high rolling mill,mill roll,Continuous casting machine,Billet continuous casting machine,Billet continuous ca

Mill Rolls Used in Steel Rolling for Section Steel

Runhao Machinery can customize various models and materials of rollers with a maximum diameter of 2000 millimeters and a maximum weight of 60 tons for customized section steel/bar/wire/plate/strip rolling mills. Rollers for the production of hot-rolled strip with a width below 1450 millimeters can also be customized.

In the field of steel rolling, rolls used for shaping section steel profiles, such as I-beams, angle steel, and channel steel, are critical processing equipment, playing a crucial role in ensuring the quality and production efficiency of the final products.

Role and Function:

Rolls for section steel are essential components in the hot rolling process. Through multiple passes of rolling, these rolls deform high-temperature metal billets, shaping them into various section steel profiles. The rolls apply continuous deformation, ensuring that the final products meet specified standards and requirements.

Types and Structure:

Rolls for section steel typically consist of work rolls and backup rolls. Work rolls directly contact the metal billets, applying pressure for rolling, while backup rolls provide support and balance, ensuring the stability of the entire rolling process.

Applicable Types of Section Steel:

These rolls find widespread application in the production of different types of section steel, including I-beams, angle steel, and channel steel. Their design and manufacturing consider the dimensions, shapes, and production requirements of various section steel profiles.

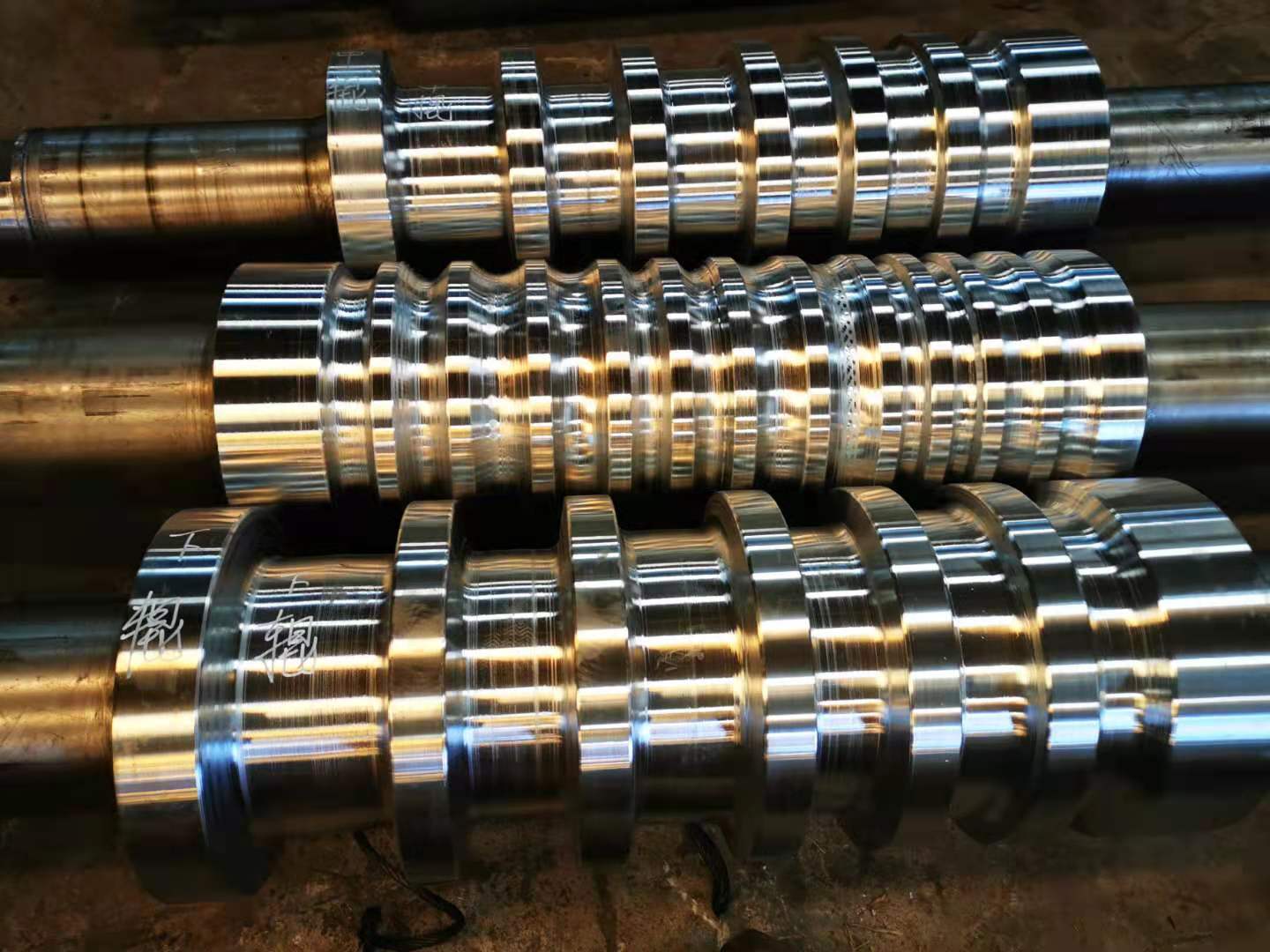

Materials and Manufacturing Process:

To withstand high temperatures and heavy workloads, rolls for section steel are often made from high-strength alloy steel or high-chromium iron. Precision heat treatment and surface treatments are employed during manufacturing to ensure superior wear resistance and high-temperature stability.

Surface Treatment:

The surfaces of these rolls undergo treatments such as chrome plating to enhance hardness, reduce friction, and extend the overall lifespan, ensuring the efficient and stable operation of the production line.

Design Features:

The design of these rolls is adaptable to accommodate different shapes and sizes of section steel. Various designs, including flat rolls, concave rolls, and convex rolls, are utilized based on the specific rolling requirements.

Rolls for section steel play a pivotal role in the steel industry, with their professional design and manufacturing being essential for ensuring both the high quality and production efficiency of section steel products.

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee