Home | HOT PRODUCTS

HOT PRODUCTS

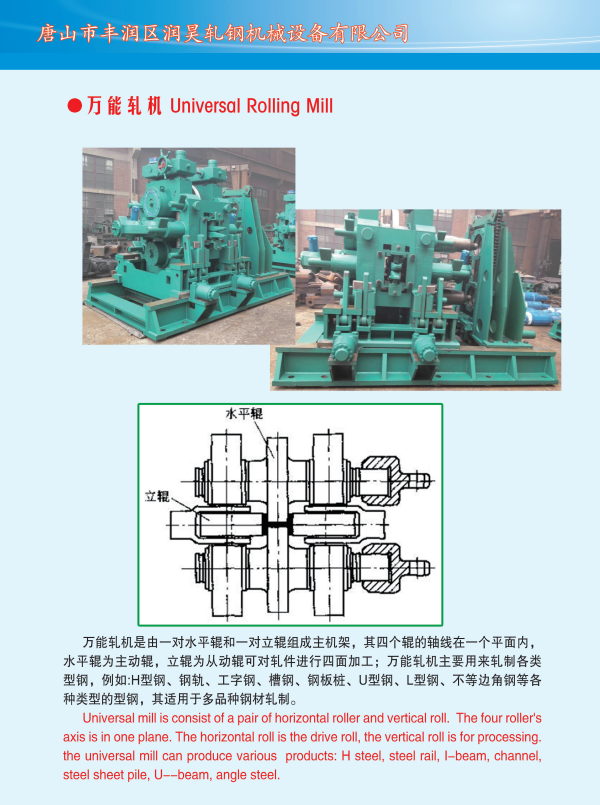

A profile rolling mill consisting of a pair of horizontal rolls and an opposing roll whose axis is in the same vertical plane.

Vertical roller can be active roller or passive roller, but the line speed of roller surface should be consistent with the horizontal roller.

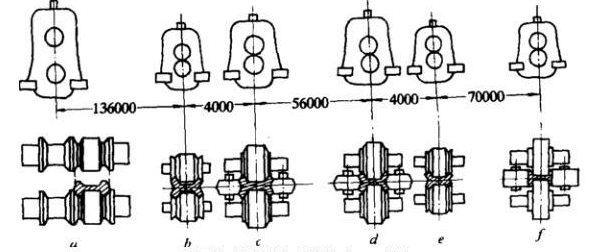

A two-high horizontal mill is usually set behind or in front of the universal mill (called the main machine), as an auxiliary forming frame (namely the edger mill), the main and auxiliary machines are reversible mills, forming continuous rolling in the rolling process.

The process of producing steel beam with universal mill is shown in Figure 1.

The advantages of universal rolling mill are as follows :(1) the complex cross section groove composed of four rollers can compress each component on the rolling piece section at the same time, so that the rolling piece deformation is more uniform, the speed difference of each part on the rolling piece section is small;

The internal stress of rolled pieces is small;

(2) Large steel can be rolled with small diameter rolls, such as I-beams with wider legs and higher waists, and H-beams without slant inside the legs;

Vertical roller can be active roller or passive roller, but the line speed of roller surface should be consistent with the horizontal roller.

A two-high horizontal mill is usually set behind or in front of the universal mill (called the main machine), as an auxiliary forming frame (namely the edger mill), the main and auxiliary machines are reversible mills, forming continuous rolling in the rolling process.

The process of producing steel beam with universal mill is shown in Figure 1.

The advantages of universal rolling mill are as follows :(1) the complex cross section groove composed of four rollers can compress each component on the rolling piece section at the same time, so that the rolling piece deformation is more uniform, the speed difference of each part on the rolling piece section is small;

The internal stress of rolled pieces is small;

(2) Large steel can be rolled with small diameter rolls, such as I-beams with wider legs and higher waists, and H-beams without slant inside the legs;

(3) The leg and waist pressure can be adjusted separately, which simplifies the adjustment of the rolling mill. Compared with the conventional rolling method, the output can be increased by 1.8 times, the operation rate can be increased by 10%, and the roll consumption can be reduced by 20%.

PREVIOUS:Short stress rolling mill

NEXT:Four high rolling mill

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee