Ancillary equipment

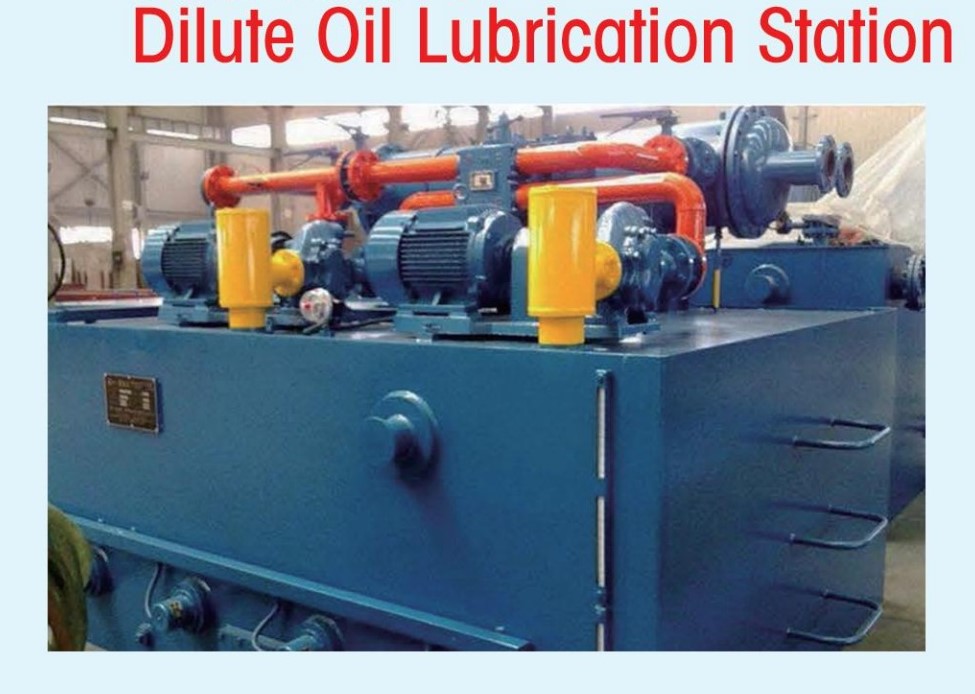

In the equipment of a hot rolling mill, the dilute oil lubrication station is a crucial component designed to provide effective lubrication for key parts of the rolling mill. Here is a detailed introduction to the dilute oil lubrication station:

1. Structure and Components:

Pump Components: The dilute oil lubrication station includes pump components responsible for pumping dilute oil from the oil storage tank to the critical lubrication points of the rolling mill.

Oil Storage Tank: The station is typically equipped with an oil storage tank to store dilute oil, ensuring the system is readily available.

Pipeline System: A complex pipeline system connects the pump components with various lubrication points on the rolling mill, ensuring the precise and stable delivery of dilute oil.

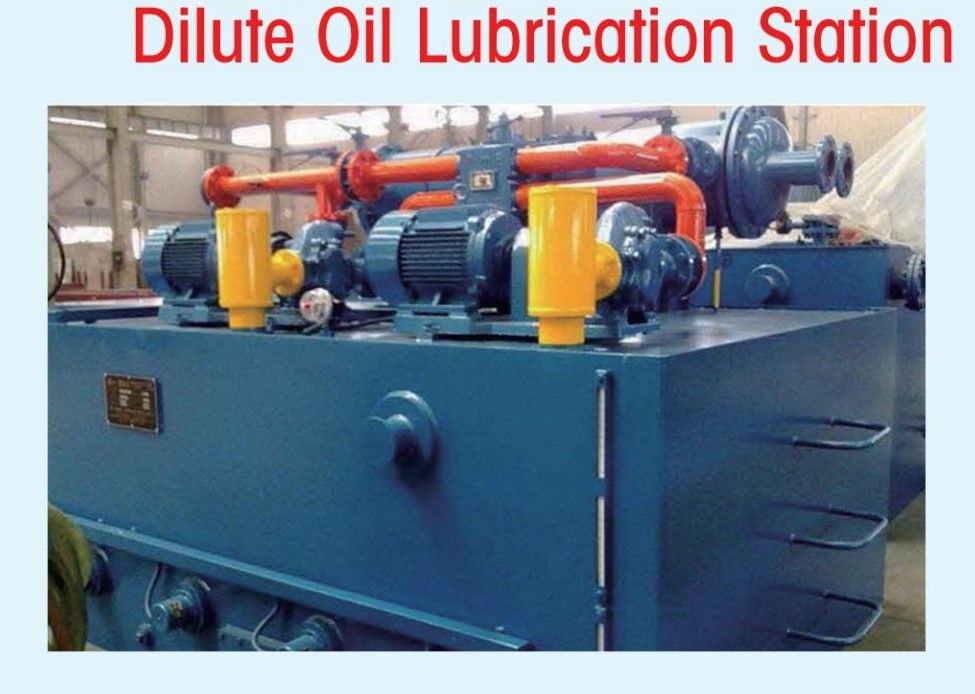

2. Functions and Applications:

High-Precision Lubrication: The dilute oil lubrication station aims to achieve high-precision lubrication for critical parts of the rolling mill, ensuring the reliability and lifespan of components during high-speed and high-load operations.

Friction Reduction: By providing an adequate amount of dilute oil, the lubrication station helps reduce friction between critical components of the rolling mill, minimizing energy losses.

Heat Dissipation: Dilute oil during the lubrication process also serves the purpose of heat dissipation, aiding in maintaining suitable working temperatures for critical parts of the rolling mill.

3. Control System:

Automation Control: Advanced dilute oil lubrication stations are typically equipped with an automation control system, capable of adjusting lubrication amounts automatically based on the operational status and demands of the rolling mill.

Pressure Monitoring: The control system may include pressure monitoring devices to ensure that each lubrication point receives lubrication at the appropriate pressure.

4. Features and Advantages:

Precision Metering: Dilute oil lubrication stations can precisely meter and distribute dilute oil, ensuring that each critical point of the rolling mill receives the appropriate amount of lubrication.

Energy Efficiency and Environmental Friendliness: By reducing frictional losses, the lubrication station contributes to increased system efficiency, promoting energy efficiency and environmental sustainability.

Extended Equipment Lifespan: Efficient lubrication helps mitigate equipment wear, extending the lifespan of various components in the rolling mill.

5. Maintenance and Safety:

Regular Inspection and Maintenance: To ensure the normal operation of the dilute oil lubrication station, regular inspections and maintenance are necessary, including cleaning pump components and replacing filters.

Safety Facilities: The lubrication station should be equipped with safety features such as emergency stop buttons and leakage monitoring to ensure the system can safely shut down in case of anomalies.

the dilute oil lubrication station plays a crucial role in guaranteeing the normal operation of equipment and extending its lifespan in a hot rolling mill, providing efficient lubrication support for the entire rolling mill.

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee