Ancillary equipment

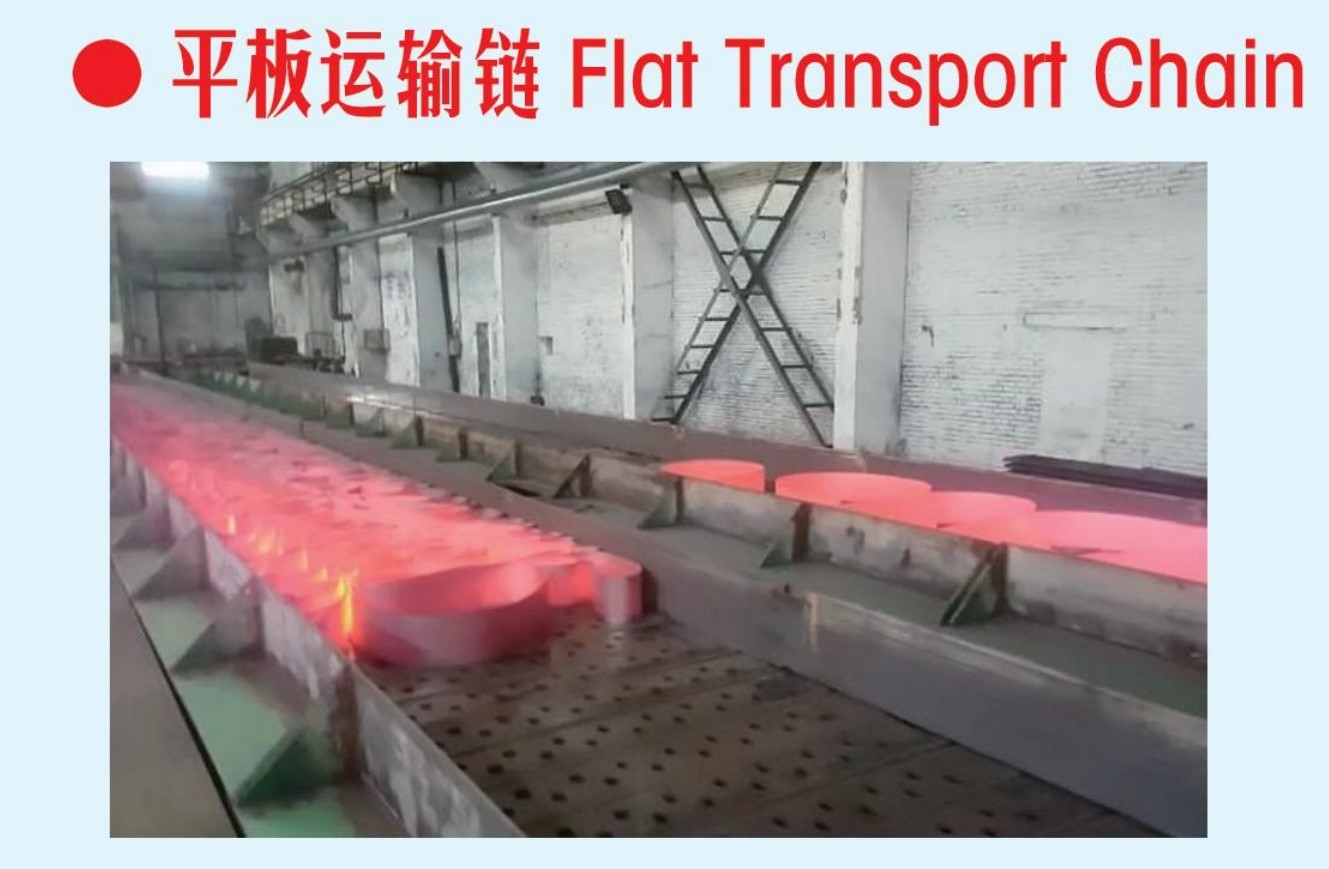

Flat Transport Chain in Hot Rolling Mill

1. Introduction:

The flat transport chain plays a critical role in the hot rolling mill, facilitating the movement of metal plates or sheets through various stages of the rolling process. This essential component ensures a smooth and controlled transportation of the material, contributing to the efficiency and precision of the overall operation.

2. Structure and Components:

Chain Links: The flat transport chain consists of a series of interconnected chain links designed to support and transport metal plates. These links are typically made of durable materials such as alloy steel to withstand the harsh conditions of the hot rolling mill environment.

Attachments: Attachments on the chain links are strategically placed to securely hold and convey the metal plates. The design of these attachments may vary based on the specific requirements of the rolling process.

Drive System: A reliable drive system is integrated with the flat transport chain to ensure a consistent and controlled movement. This system may include motors, gearboxes, and other components to drive the chain effectively.

3. Functions and Applications:

Plate Transportation: The primary function of the flat transport chain is to move metal steel plate or sheets from one processing stage to another within the hot rolling mill. This includes transporting the material through the entry and exit guides, the rolling stands, and other relevant sections.

Speed Control: The flat transport chain allows for precise control over the speed of plate movement. This control is crucial for maintaining the desired rolling parameters and achieving the specified dimensions and properties of the final product.

4. Features and Advantages:

High Strength and Durability: The chain is designed to withstand the heavy loads and harsh conditions of the hot rolling mill environment, ensuring longevity and reliability.

Precision and Consistency: The flat transport chain contributes to the precision and consistency of the rolling process, playing a crucial role in achieving high-quality end products.

Adaptability: The design of the flat transport chain can be adapted to accommodate various plate sizes and thicknesses, making it a versatile component in the mill.

5. Maintenance and Safety:

Regular Inspection: Periodic inspections and maintenance are essential to ensure the proper functioning of the flat transport chain. This includes checking for wear, lubrication, and any potential issues that could impact performance.

Safety Features: Safety features such as emergency stops and protective guards are often incorporated to enhance the overall safety of the operation.

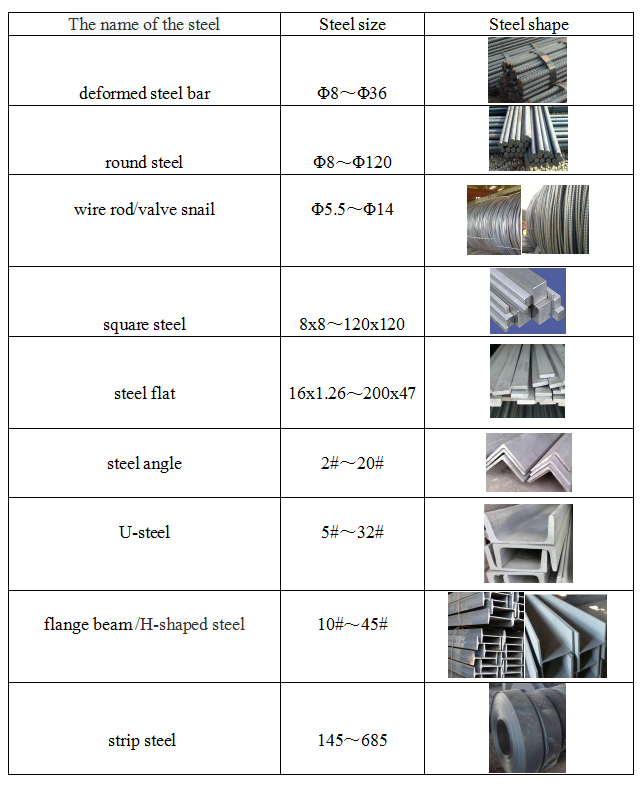

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee