Ancillary equipment

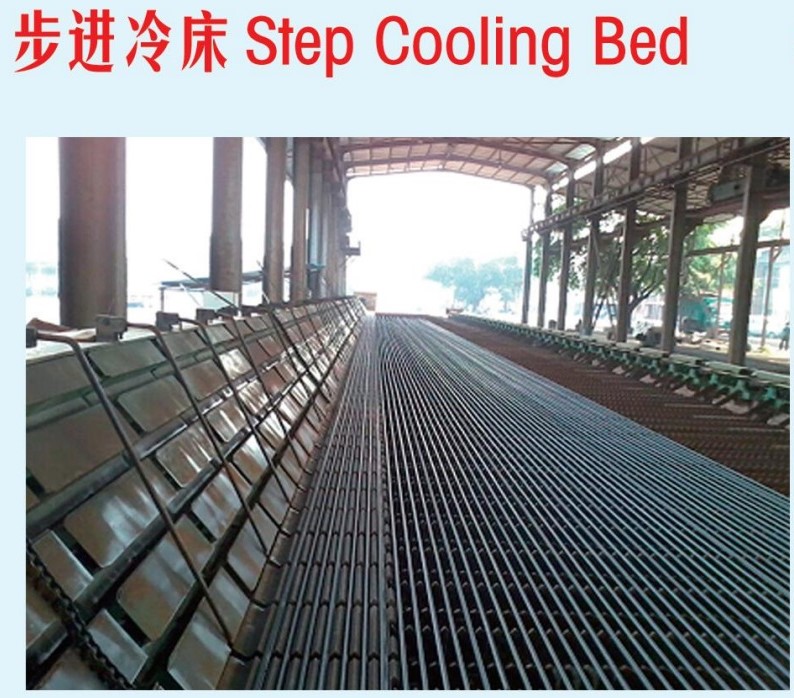

Step Cooling Bed in Hot Rolling Mill

1. Operating Principle:

The Step Cooling Bed is typically located at the exit of a hot rolling mill and operates by conveying hot-rolled metal sheets or profiles to the cooling area through a series of step beams. In the cooling zone, the metal sheets are subjected to cooling devices, such as water tanks or air-cooling units, to rapidly reduce their temperature. The distinctive feature of the Step Cooling Bed lies in its utilization of step beams, enabling a gradual movement of metal sheets during the cooling process.

2. Structural Components:

Step Beam System: The core of the Step Cooling Bed is the conveyor system consisting of step beams. Each step beam operates independently, moving metal sheets from one position to the next.

Cooling Devices: Cooling devices include water tanks, spray heads, or air-cooling units designed to extract heat rapidly from the surface of metal sheets, facilitating quick cooling.

Straightening Mechanism: Some Step Cooling Beds are equipped with a straightening mechanism to adjust and align the cooled metal sheets, ensuring they meet specified dimensions and shapes.

3. Features and Advantages:

Gradual Cooling: The Step Cooling Bed, through its step beam system, ensures a gradual movement of metal sheets in the cooling area, allowing for sufficient cooling time and improving product quality.

Versatility: The Step Cooling Bed is adaptable to various shapes and specifications of metal sheets or profiles, displaying strong production adaptability.

Automation Control: Modern Step Cooling Beds often feature advanced automation control systems that monitor the temperature and shape of metal sheets in real-time, automatically adjusting the cooling and straightening processes.

4. Applications:

The Step Cooling Bed is primarily employed for processing hot-rolled metal sheets, profiles, or rebar and finds extensive application in industries such as construction, bridges, and rail transportation.

5. Development Trends:

With technological advancements, Step Cooling Beds are evolving towards intelligent, efficient, and environmentally friendly solutions. The application of new cooling technologies and automated control systems is expected to further enhance the production efficiency and product quality of Step Cooling Beds.

The Step Cooling Bed plays a critical role in the hot rolling production line, offering irreplaceable contributions to ensuring product quality and improving production efficiency.

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee