Ancillary equipment

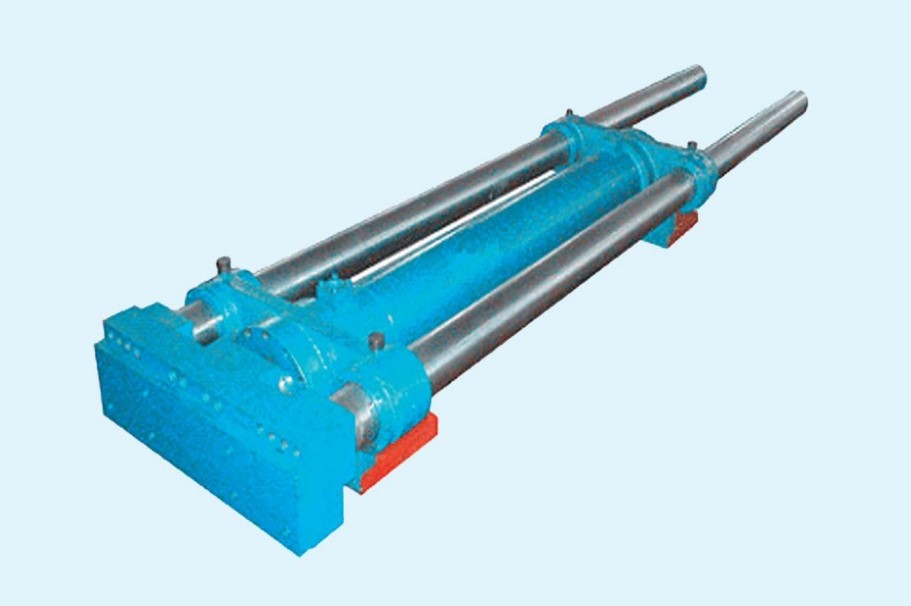

Steel Pusher in Hot Rolling Mill Equipment:

In the equipment of a hot rolling mill, the steel pusher is a crucial auxiliary device designed to systematically push metal billets into the working area of the rolling mill. This ensures that the metal achieves the desired shape and dimensions throughout the entire rolling process. Here is a detailed introduction to the steel pusher, taking into consideration its role in reducing roller table wear:

1. Structure and Working Principles:

Steel Pusher Framework: Typically composed of a robust steel structure, the steel pusher includes a driving mechanism and a guiding system. The driving mechanism, powered by either mechanical transmission or a hydraulic system, propels the metal billets.

Pushing Wheels: Equipped with pushing wheels featuring a specially designed surface to ensure uniform pushing force on the billets.

2. Functions and Applications:

Coordination with Rolling Mill: The steel pusher works in coordination with the rolling mill, systematically pushing metal billets from the feeding area into the working zone of the mill, ensuring smooth entry for efficient rolling operations.

Shape and Size Control: Through precise pushing force and guidance, the steel pusher helps maintain the correct position of metal billets within the rolling mill, ensuring the final product meets the required shape and dimensions.

3. Types and Adjustments:

Mechanical Steel Pusher: Utilizes a mechanical transmission system to push metal billets and typically includes adjustable features to accommodate different billet specifications.

Hydraulic Steel Pusher: Uses a hydraulic system for pushing, providing more flexible adjustment capabilities to tailor pushing force and speed as needed.

4. Safety and Control:

Safety Features: The design of the steel pusher includes safety features such as protective covers and emergency stop buttons to ensure quick shutdown when necessary, ensuring the safety of personnel.

Automation Control: Advanced steel pushers may be equipped with an automation control system, utilizing sensors to monitor the position and status of billets for automatic adjustments and control.

5. Reduction of Roller Table Wear:

Wear Reduction Design: The pushing action of the steel pusher contributes to reducing the workload on the roller table, minimizing wear and extending the lifespan of the roller table.

6. Adaptability and Maintenance:

Adaptation to Different Billets: The design of the steel pusher takes into account the need to handle various types and specifications of metal billets, catering to the diversity of the hot rolling mill production line.

Regular Maintenance: To ensure the long-term reliable operation of the steel pusher, regular maintenance is essential, including cleaning, lubrication, and inspection of key components for wear.

The steel pusher in hot rolling mill equipment plays a critical role in pushing metal billets, ensuring efficient and precise metal rolling operations, and contributes to extending the lifespan of the roller table by reducing its workload.

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee