rolling mill

Vertical Steel Rolling Production Line

- speed:3m-35m/s

- Rolled billet dimensions:40-250

- Equipment model:280~650

- Roll diameter:φ300-700

- Product description: vertical steel rolling production line, steel rolling mill, rolling mill, hot strip mill,

Vertical Steel Rolling Production Line:

The vertical steel rolling production line is a crucial equipment in the field of hot rolling, designed for the rolling and processing of metal materials of different specifications and shapes. Here is a detailed overview of the vertical steel rolling production line:

1. Structural Components:

Inlet System: Metal billets first enter the vertical steel rolling production line through the inlet system. This system typically includes conveying equipment and alignment mechanisms to ensure proper positioning and alignment of the billets before entering the rolling section.

Rolling Mill Unit: The core of the vertical steel rolling production line consists of a series of vertically arranged rolls. These rolls are used for the plastic deformation of metal billets, gradually giving them the desired shape and dimensions in the vertical direction.

Cooling System: After rolling, the metal material passes through a cooling system, usually a water-cooling system, to control the temperature and stabilize the metal structure. This helps improve product quality and mechanical properties.

Exit System: The final metal products leave the vertical steel rolling production line through the exit system. This includes conveying equipment and possibly cutting or length-measuring devices to ensure the final product meets specifications.

2. Working Principle:

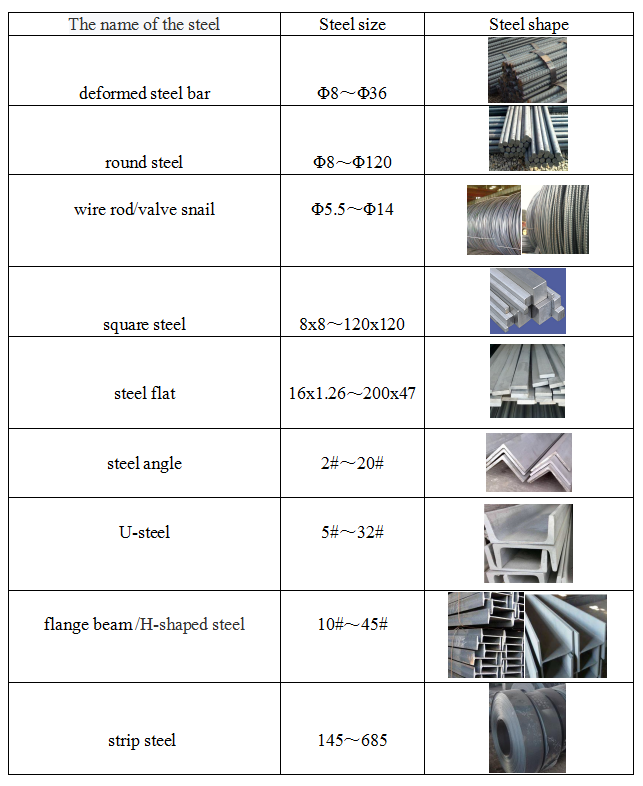

The working principle of the vertical steel rolling production line involves adjusting the layout and pressure of the rolls to induce plastic deformation of the metal billets in the vertical direction. This design allows for the production of metal products with various cross-sectional shapes, such as square steel, angle steel, and more.

3. Application Areas:

The vertical steel rolling production line finds widespread applications in construction, manufacturing, transportation, and other fields. It is suitable for the production of metal products with special cross-sectional shapes, such as beams, columns, and structural steel.

4. Advantages and Features:

Diverse Product Range: Due to the nature of vertical rolling, the vertical steel rolling production line can produce a variety of shapes and specifications of metal products.

High Production Efficiency: It has high production capacity, suitable for large-scale and continuous production requirements.

Stability and Precision: Through advanced control systems, it ensures stability in the production process and precision in the final product.

Categories

Latest News

Contact Us

Contact: Ed Lee

Phone: +86 13613237999

Tel: +86 13613237999

Email: lihaoye@chinarunhao.com

Add: Runhao steel rolling machinery, dalinggongzhuang village, Fengrun District, Tangshan City, Hebei Province

Ed Lee

Ed Lee